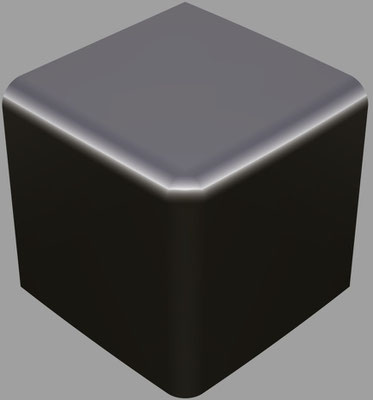

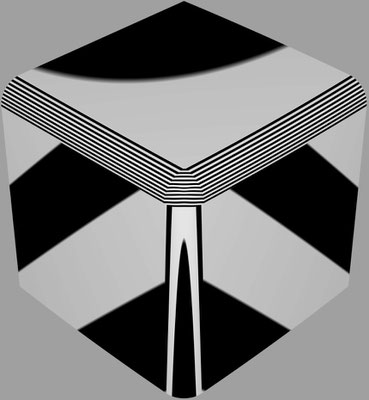

differences between class-A and class-B

Class-B surfacing

You can see the connection between the surfaces.

This happens if the edges are filled with a common CAD software

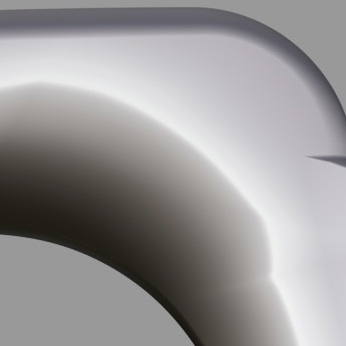

Class-A surfacing

Floating connection between surfaces. It looks as if there is no beginning or ending. These fillets are made with Alias Surface

Here are a few examples.

These are already existing products, which I have corrected as follows:

These products are models that have been designed. On the basis of my optimization new tools were built.

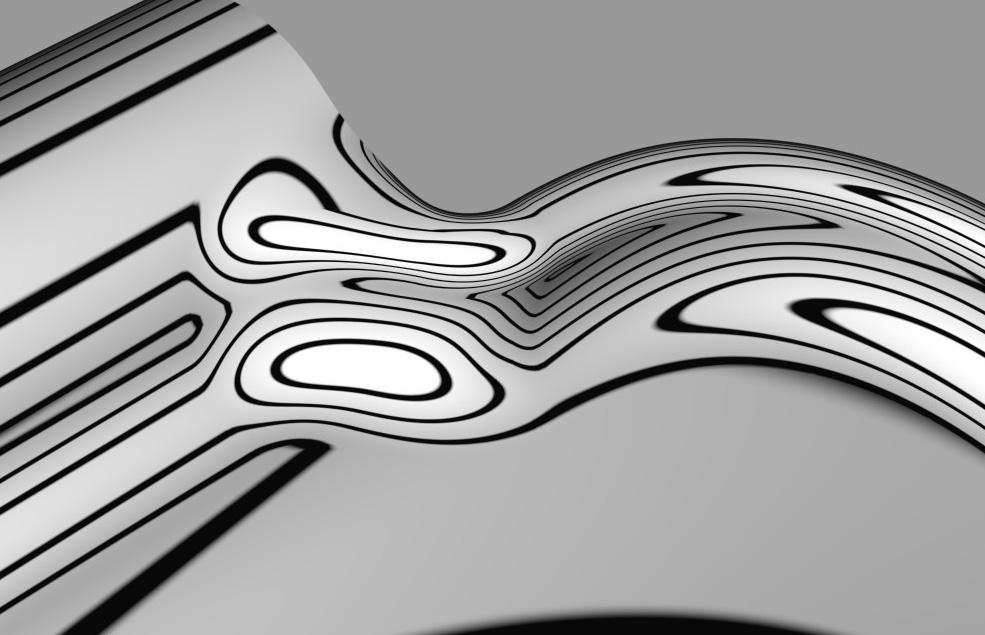

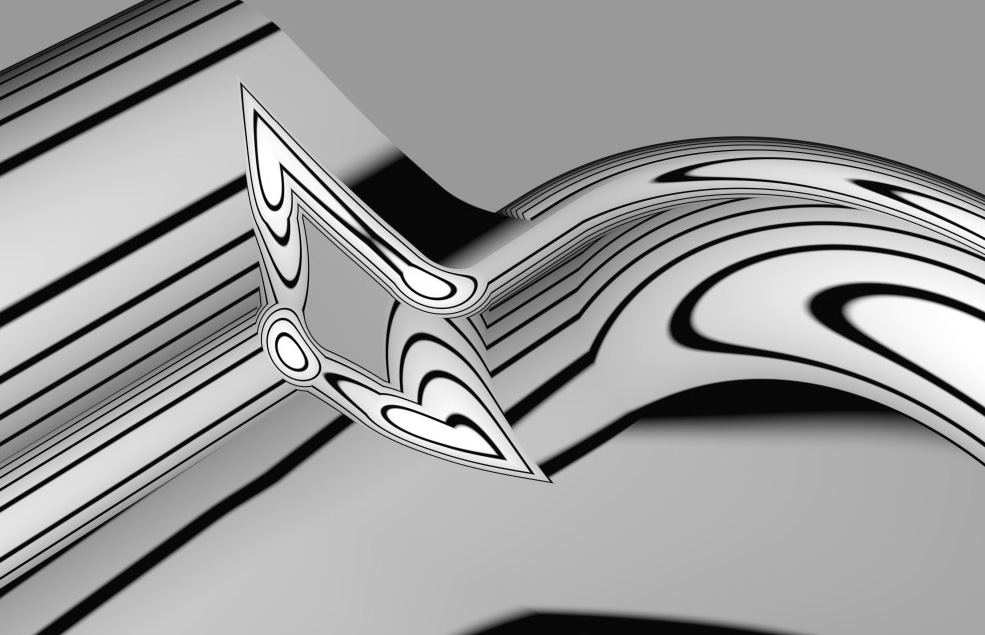

- Attractive surface quality. If a product has surface defects, this product is quickly classified as "cheap". Professional highlighted surfaces automatically increase the value of a product.

- Constructed wall thicknesses are uniform but also unsightly. Modeling wall thicknesses are nice but not equal. The reason is that CAD techniques can't "control" the surfaces, and modelers haven't the knowledge of manufacturing processes. In order to be able to produce cost-efficiently, I had to combine both.

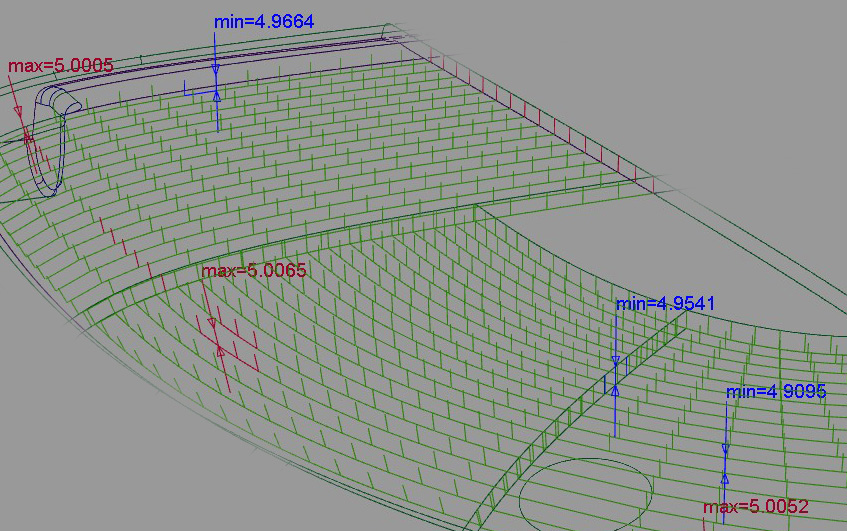

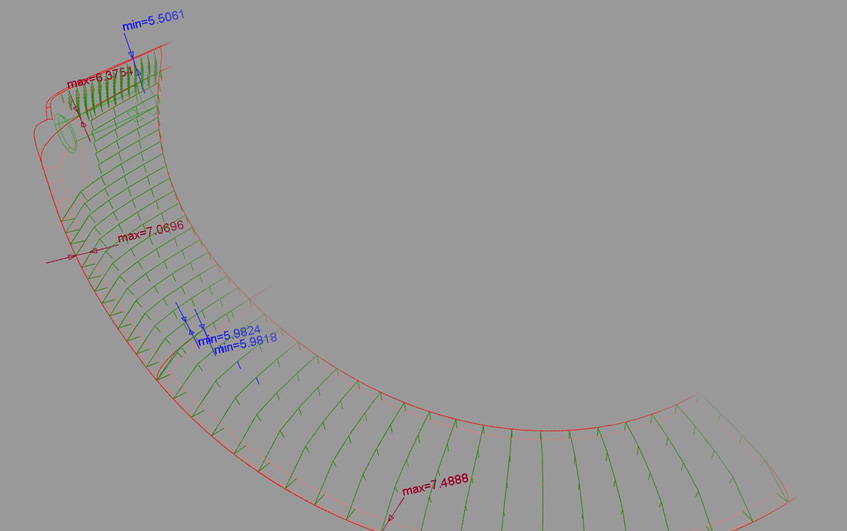

The difference between construction and modeling is clearly visible.

The highlights can often not be displayed professionally with normal CAD programs. Unfortunately, you can only see the result after the mold has been built.

Also here you can see clearly how to correct the highlights before it is too late and the shape is already milled.

Not everybody sees what is wrong exactly but everybody sees that something is wrong

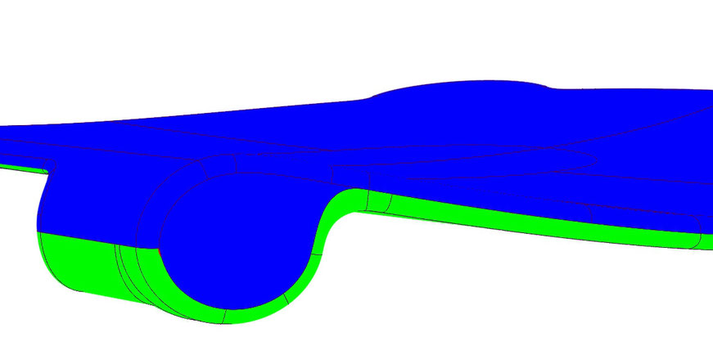

Wall thicknesses good vs. bad.

Uneven wall thicknesses unnecessarily slow down the production process.

Here the wall thickness was not done by a technician it was done by a modeler. Unfortunately, the modeler had less experience in the field of plastic molding, so I had to correct the wall thicknesses afterwards.

Mould release line /splitline

The tool separation often determines whether a tool is inexpensive to produce or becomes unnecessarily complex. Therefore I make absolutely sure that there is a separation from the very beginning. A change in the separation often results in a complete restoration of the component. Watch this: